Bao-BOX

Carnegie Mellon University, Pittsburgh, USA

Design for the Environment | Team Project | Nov - Dec 2017 (4 weeks)

TEAM

Mark Byrne | Alok Joshi | Lauren Romero

Guanqiao Yin | Melin Zhang | Ke Zheng

MY ROLE

User Research | Literature Review

Material Exploration | Concepts

Prototyping | Usability Testing

Report Formatting

Team BAO focused on the opportunity of designing a product that will significantly benefit the environment in the fast food industry. We focused on reducing environmental impact through reducing waste produced by packaging in the take-away food industry.

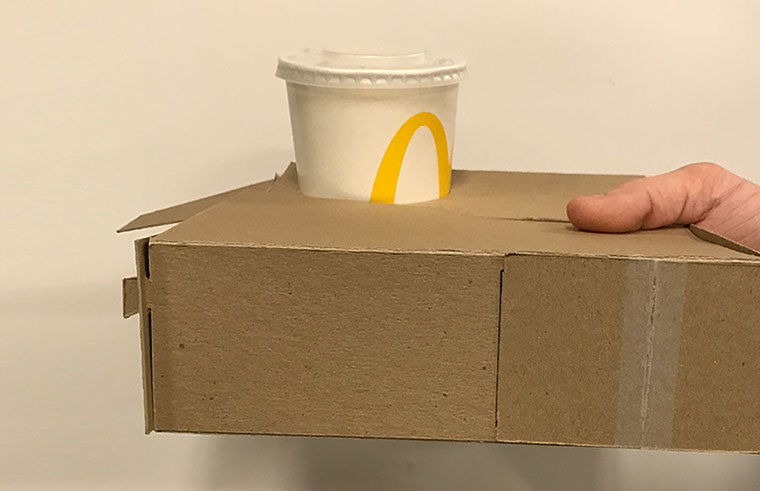

The BAO box reduces the number of packagings for the average McDonald’s meal from three pieces to one while also cutting down the amount of material used for packaging and increasing the amount of material that is recycled. Moreover, it involves the consumer by motivating them to make a beneficial environmental impact and decrease the amount of paper that ends up in the landfill.

A significant environmental improvement of 26% with the BAO box compared to traditional methods is predicted by Sustainable Minds software and many more options are foreseeable in the future.

RECOGNIZE

It is a shocking statistic that 50% of street litter is from fast food restaurants, with McDonald’s packaging among the most frequently found.1 As the biggest food giant in America, McDonald’s has 35,000 locations states wide and serves 75 hamburgers per second.2 Fast food brings convenience, but every useful function comes at a cost and unfortunately also represents the biggest source of litter.

Most of the packaging given to these customers ends up on the streets as litter or in the trash. In addition to that, even people who eat inside the restaurant get the unnecessary to-go packaging. Meanwhile, not only the combination of paper, plastic, wax and metal parts makes the packaging difficult to recycle, but once the paper is soiled, all packaging ends its life in a landfill.3

Based on all these facts, it has become quite clear that even a small change in being more environmentally friendly in fast food industry will create huge environmental impact across the globe.

50 million

people a day visit a Fast-food restaurant in America. Most of the packaging ends up in the garbage.

A meal deal comprises of a separate container for each item with an additional carrying bag.

McDonalds sells an average of 75 hamburgers per second.

Once soiled with grease, cheese, and other foodstuffs, the paper is difficult to recycle, so all packaging is sent to landfill.

People are becoming more aware of their effect on the planet, and search for Eco-friendly practices that have minimal impact on the environment. With this awareness, brands are tasked to provide environmentally responsible packaging and recycling.

ANALYZE

Taking into account the stats and figures uncovered in our research phase, we then looked towards McDonalds and uncovered their Sustainable Packaging Strategy which they hope to achieve by 2020. To define our design criteria for this 'Design for Environment' project, we took guidance from their strategy to create our own unique holistic approach, incorporating Design, Sourcing and Recovery answering ENVIRONMENTAL concerns. In addition, through our primary research, we uncovered some ERGONOMIC issues with the current packaging which would also help to determine our final design

‘McDonald’s Journey Towards Sustainable Fiber-Based Packaging - WE’RE HALF WAY THERE.’ May 2016

Source 100% of fiber-based packaging from recycled or certified sustainable sources by 2020.

Achieve zero deforestation for all fiber sourcing under their global commitment to deforestation.

- DESIGN – Optimize weight and simplify the number of materials used in our packaging

- SOURCING – Increase the use of recycled and certified sustainability sourced raw materials

- RECOVERY – Work to use recoverable packaging with viable end-of-life options

McDonald’s Sustainable Packaging Strategy

ENVIRONMENT

- Separate container for each item

- One bag to hold all items

- Thrown in the trash when done

ERGONOMICS

- Two hand operation

- Cold Drink

- Hard to share

- Hard to snack

VISUALIZE

From our research and the insights uncovered in the Recognize and Analyze stages, we outlined five guiding principles that would determine the criteria upon which we would design our solution.

1. MATERIAL

100% recycled paper was chosen over plastic and bio-plastic due to its low impact on the environment during manufacture and easier integration into McDonald's current structures.

2. ERGONOMICS

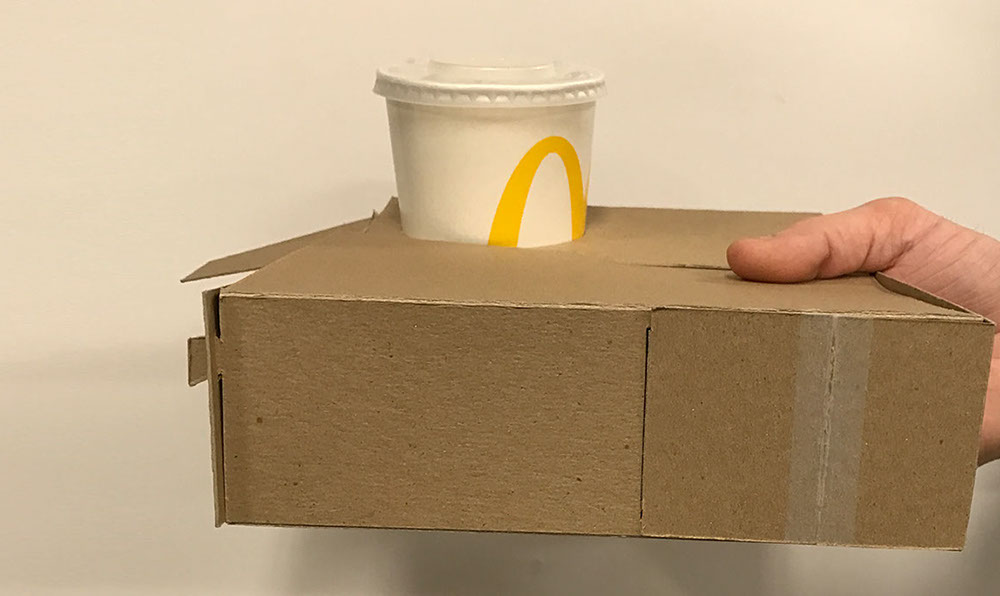

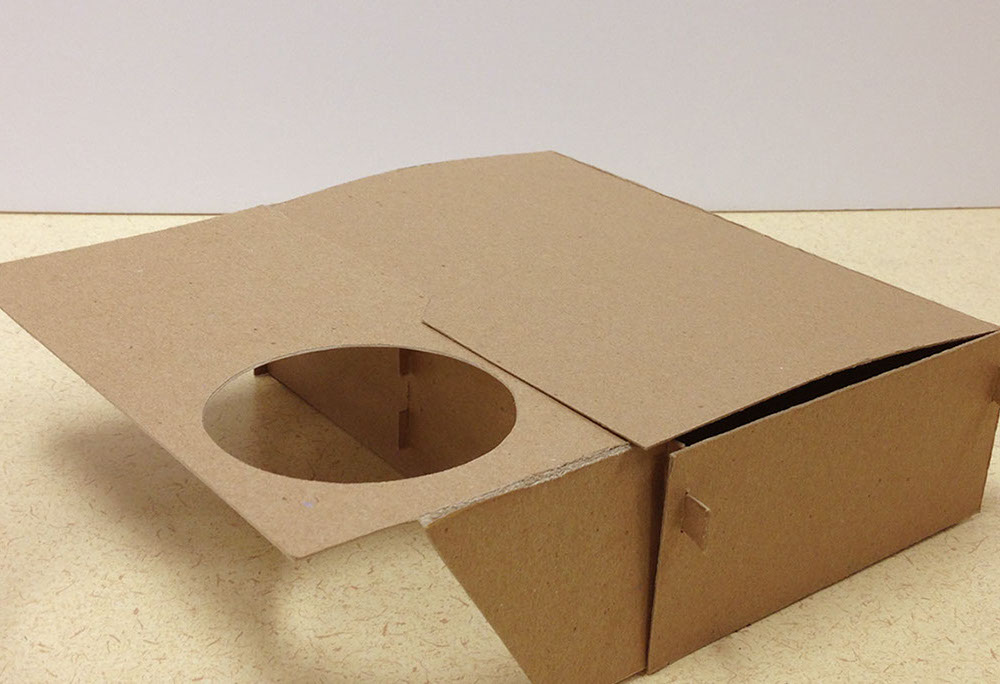

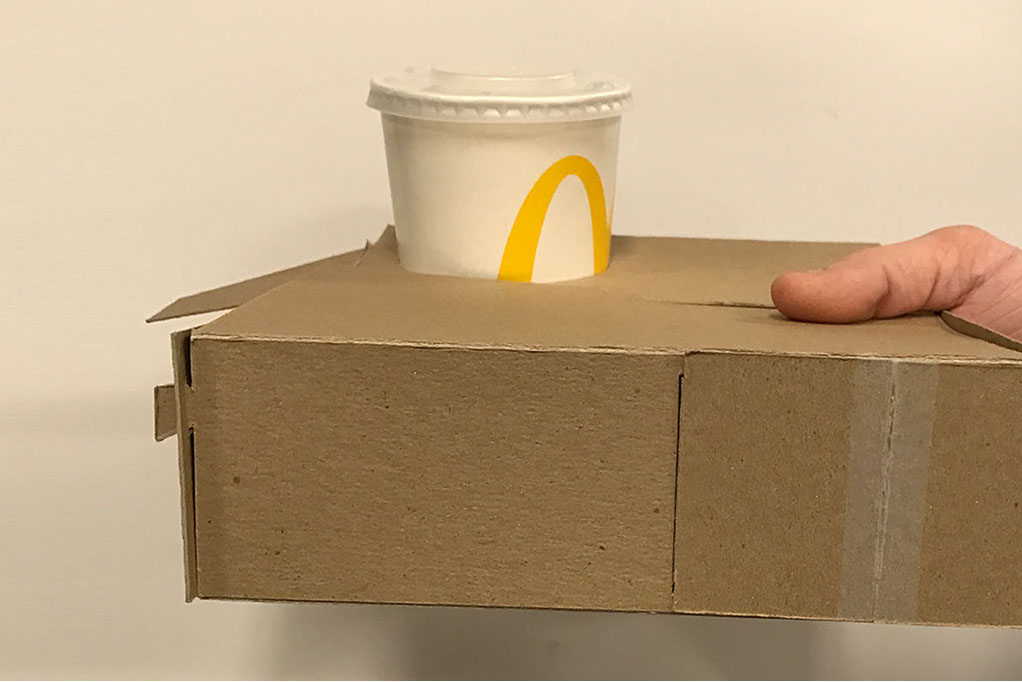

The box should have a lid or cover, be held by one hand, and allow the user to not need to hold onto the cold drink (which would lead to discomfort).

3. POLICY

The only drawback of using paper is that it cannot be recycled if it has oil from foodstuffs on it. There needs to be the implementation of a collection system and policy, the paper that would otherwise end up in the trash could be recycled and used again.

4. DESIGN for the ENVIRONMENT

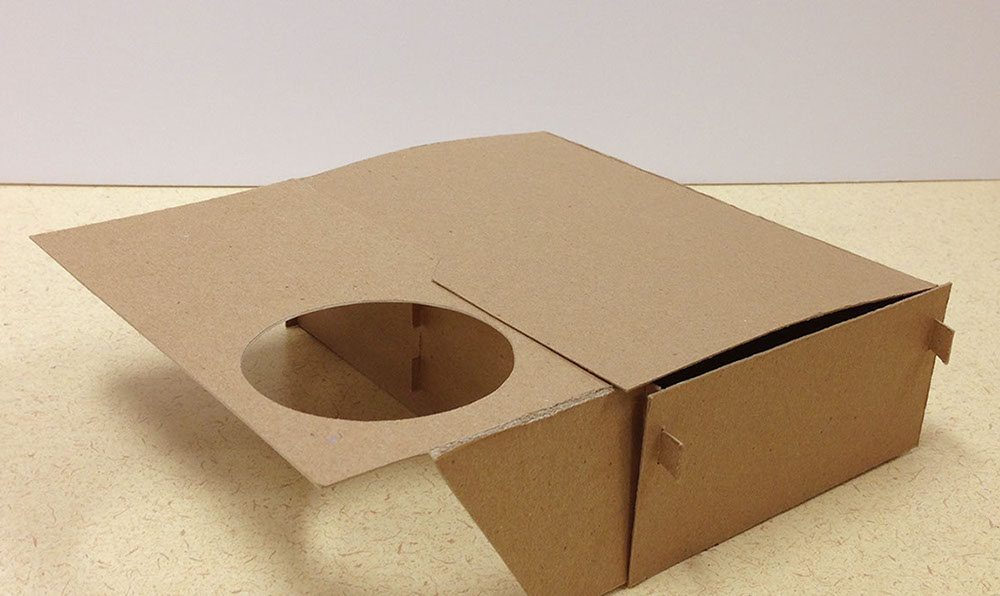

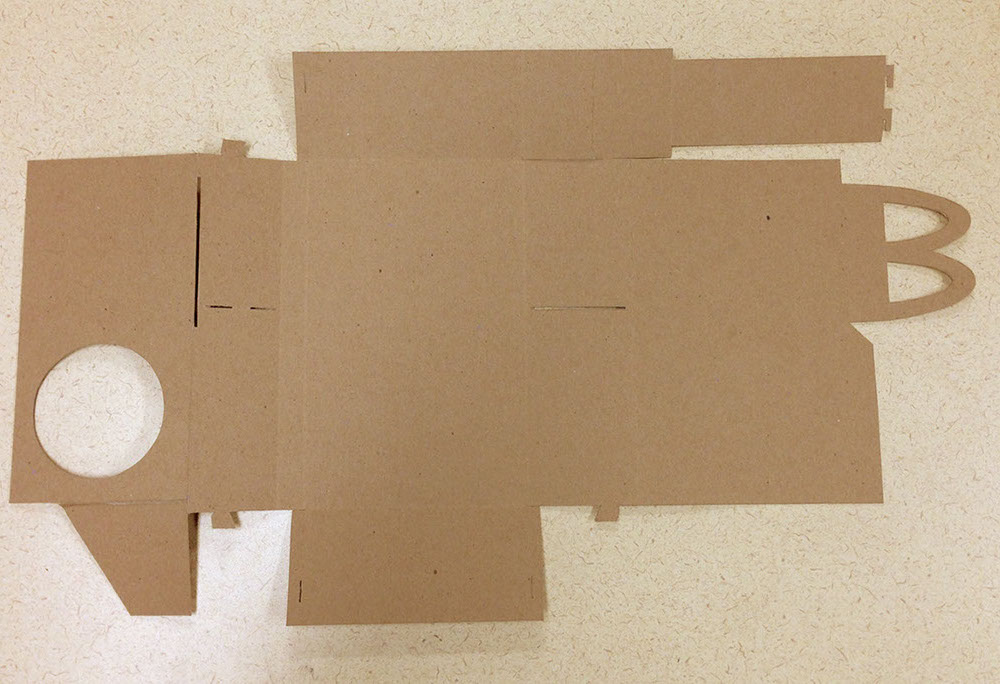

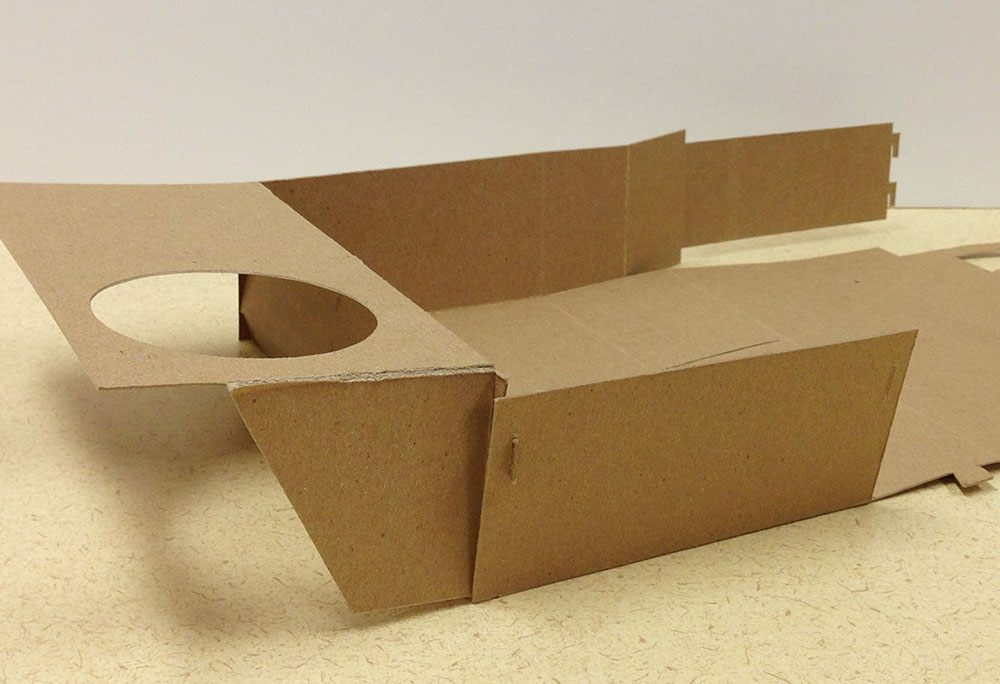

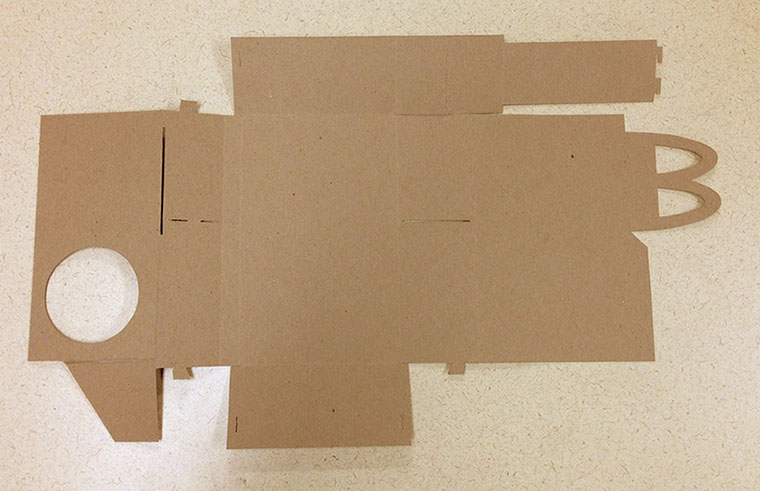

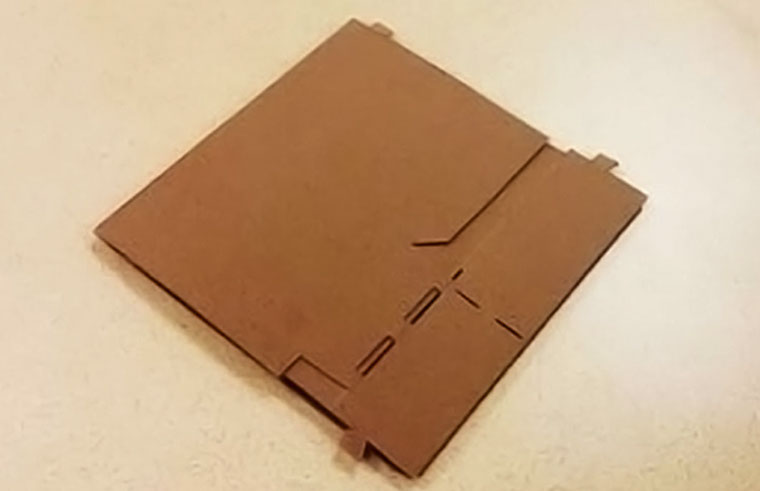

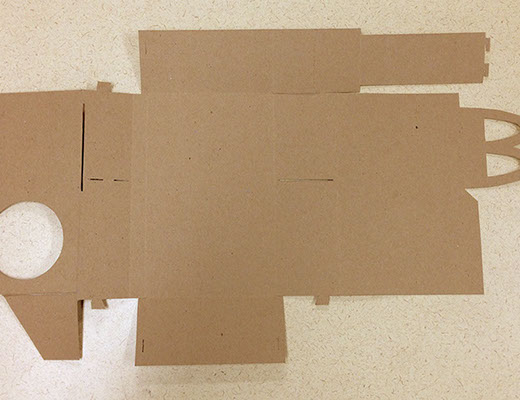

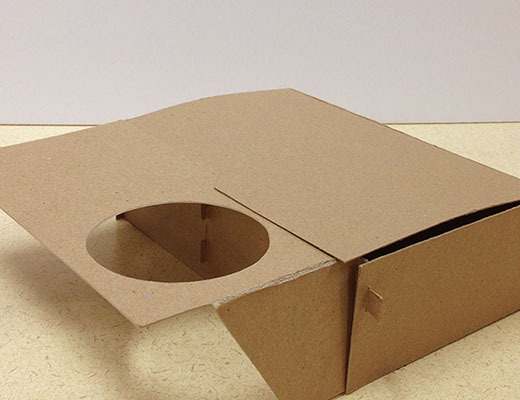

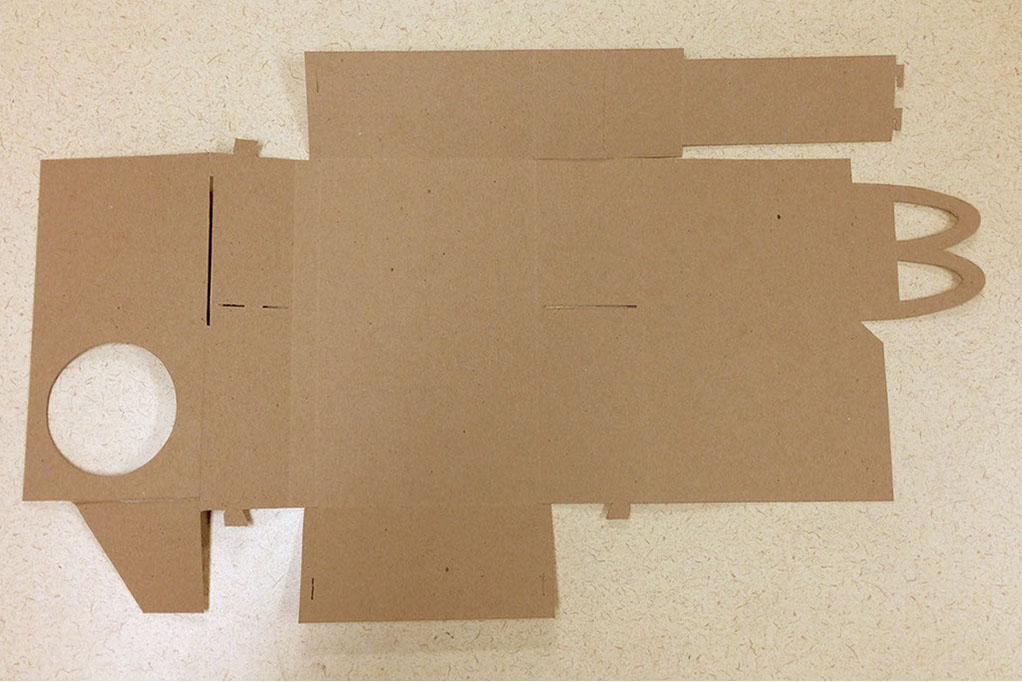

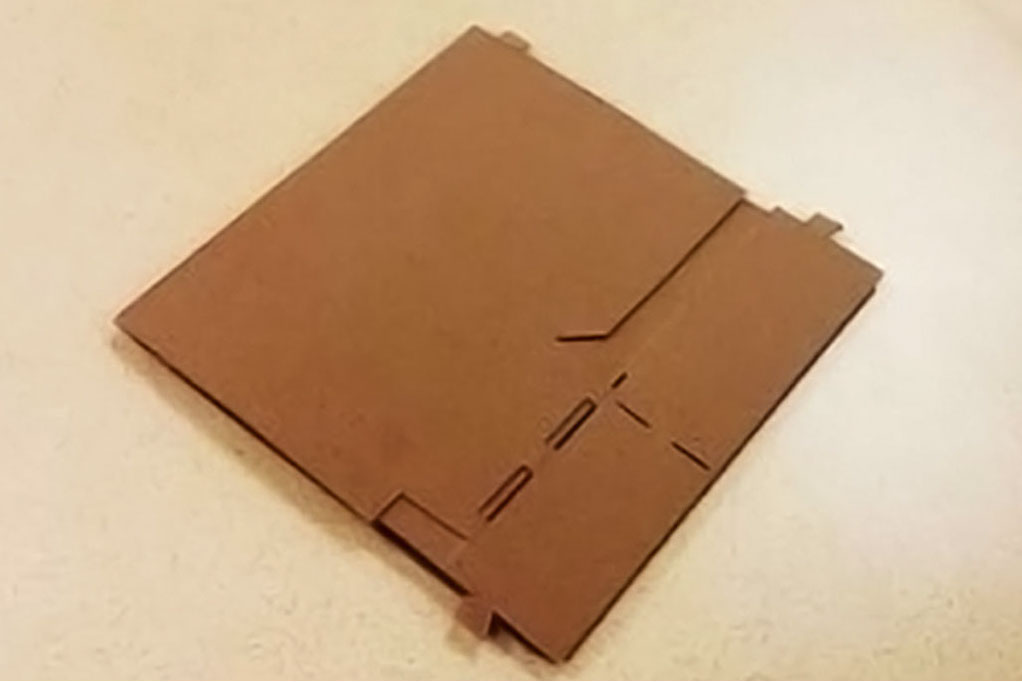

To reduce manufacturing costs, BAO box should be made from one piece of material without the need for any adhesive. It should fold together and be strong enough to hold the food, and easily destructed to be returned to McDonald’s.

5. MOTIVATION

Get McDonald's 70 million customers involved by offering credits or rewards as incentives to return used packages for recycling.

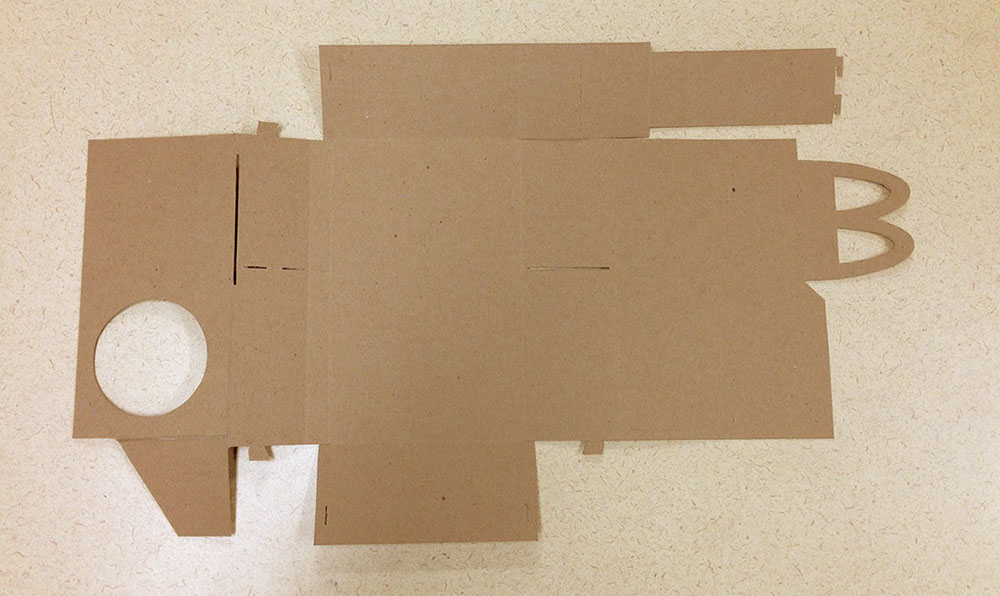

What about just one sheet of material?

That can be folded in-store into a container?

And later flat-packed for easy recycling?

CONCEPTUALIZE

<

>

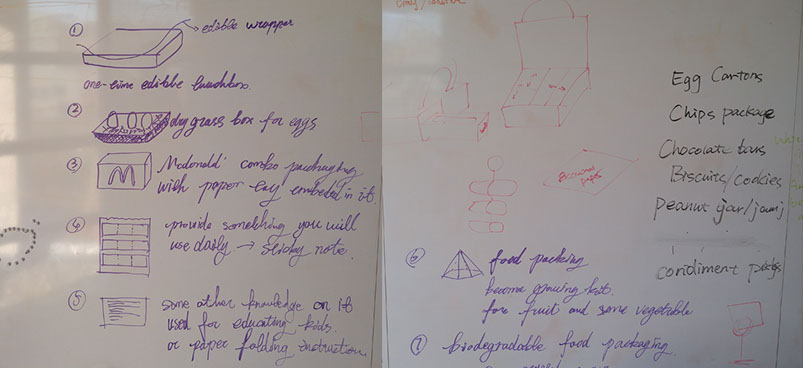

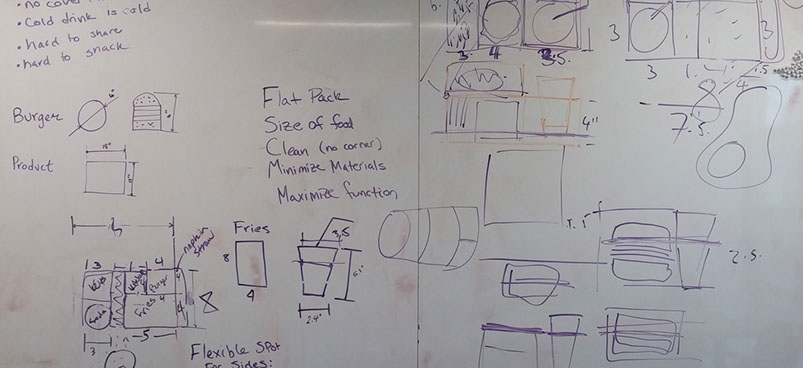

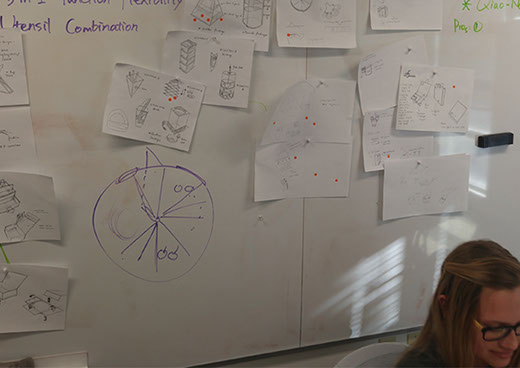

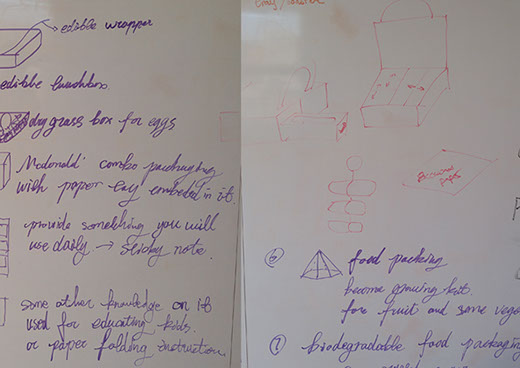

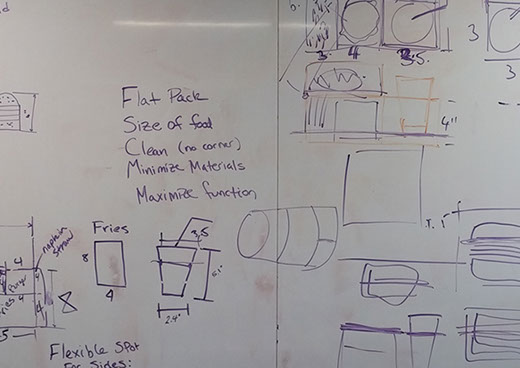

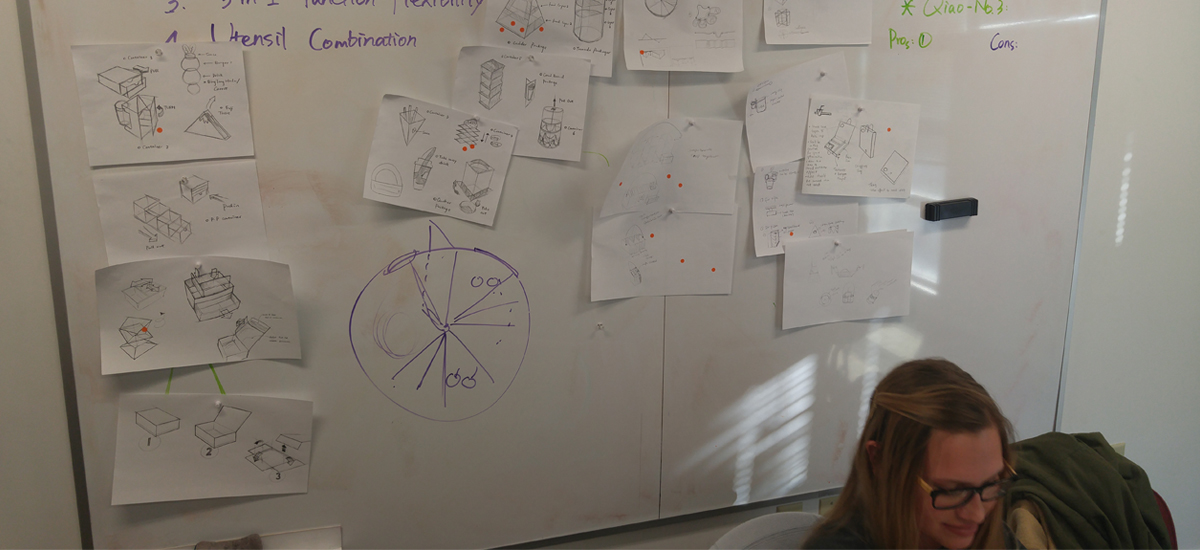

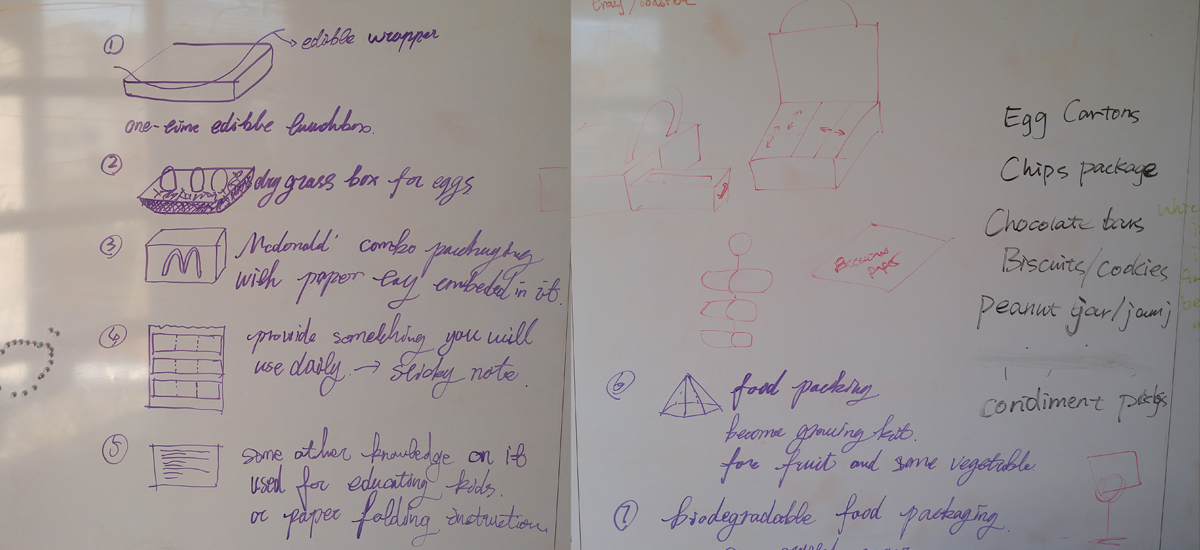

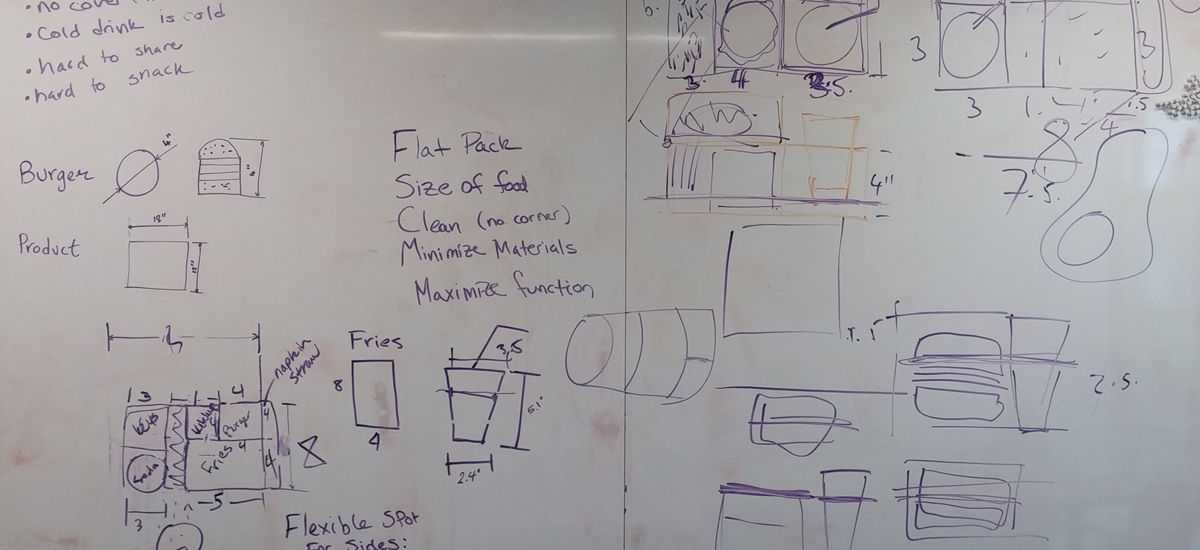

At this stage we split to prepare a number of individual concepts that would satisfy the criteria, then we returned and used the white-board to pin up our ideas. After much discussion, a final concept was chosen to be developed further. This then sent the team into a flurry sketching and illustrating further ideas and variations on the white-board, with each member adding to existing concepts with further features and improvements.

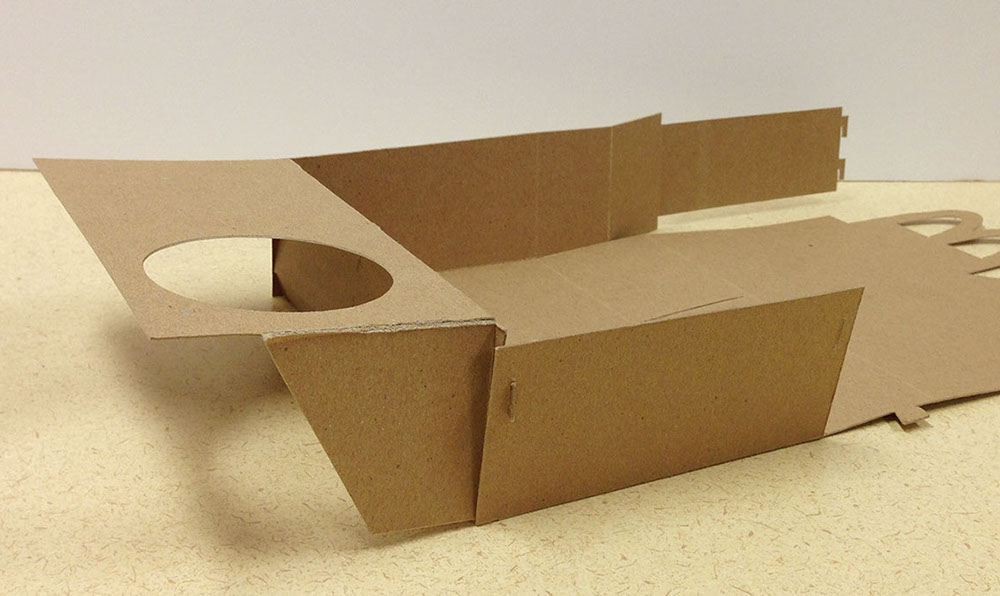

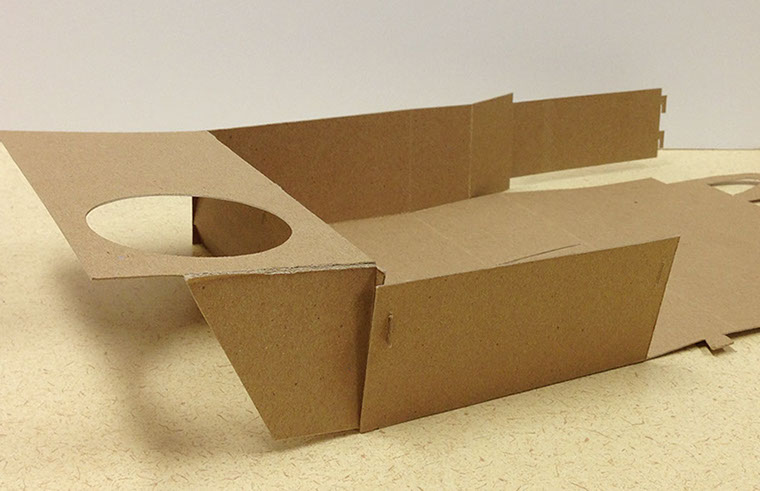

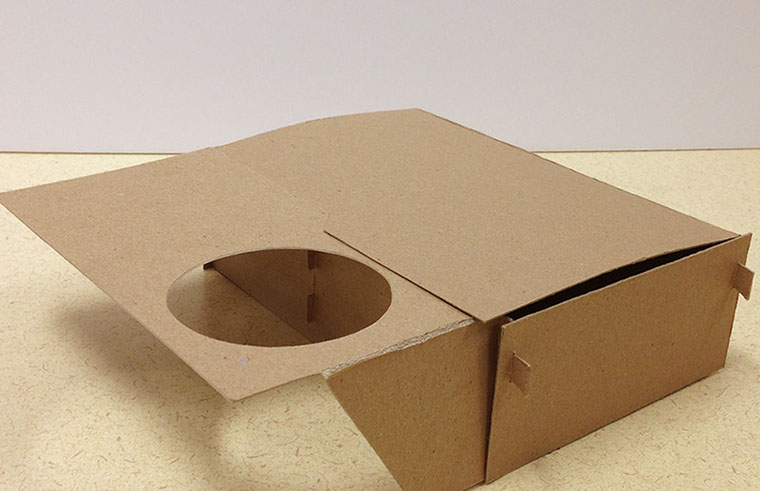

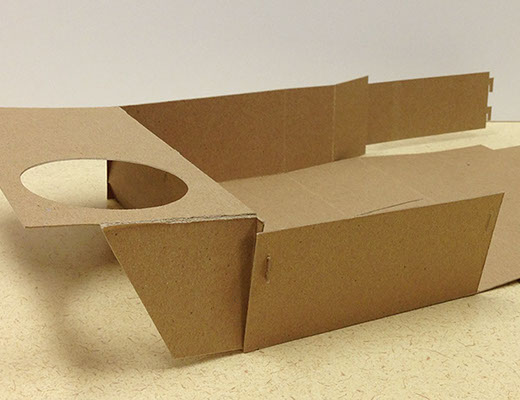

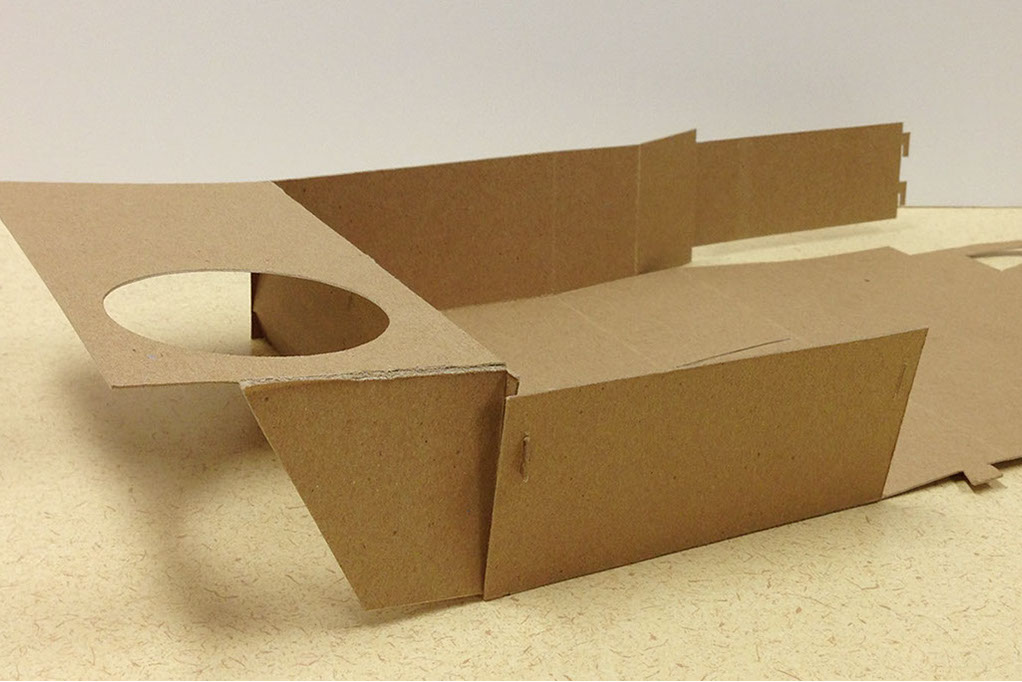

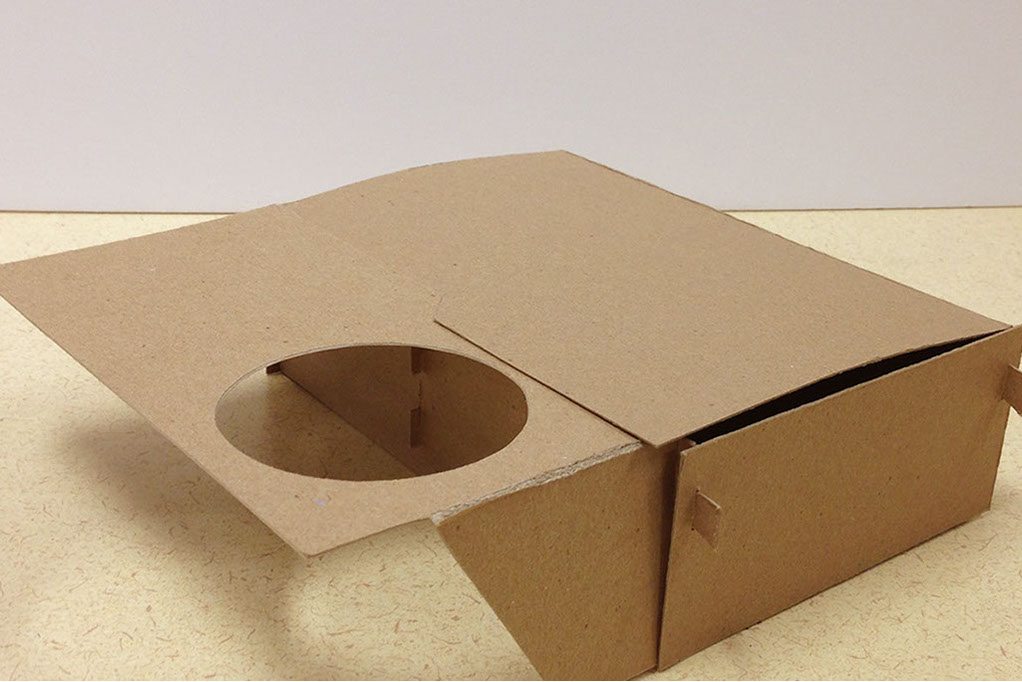

To design the overall size of the box and the compartments inside, research was done to learn the exact sizes of common meal items from McDonald’s such as the burger, fries, and condiment packages. These measurements were moved around in different combinations to find the most optimal design configuration. After the sizes were decided, the box was prototyped several times to determine the optimal BAO box dimensions.

This final concept was a lunch box design that would hold a drink container and compartmentalize the food into three sections.

SCRUTINIZE

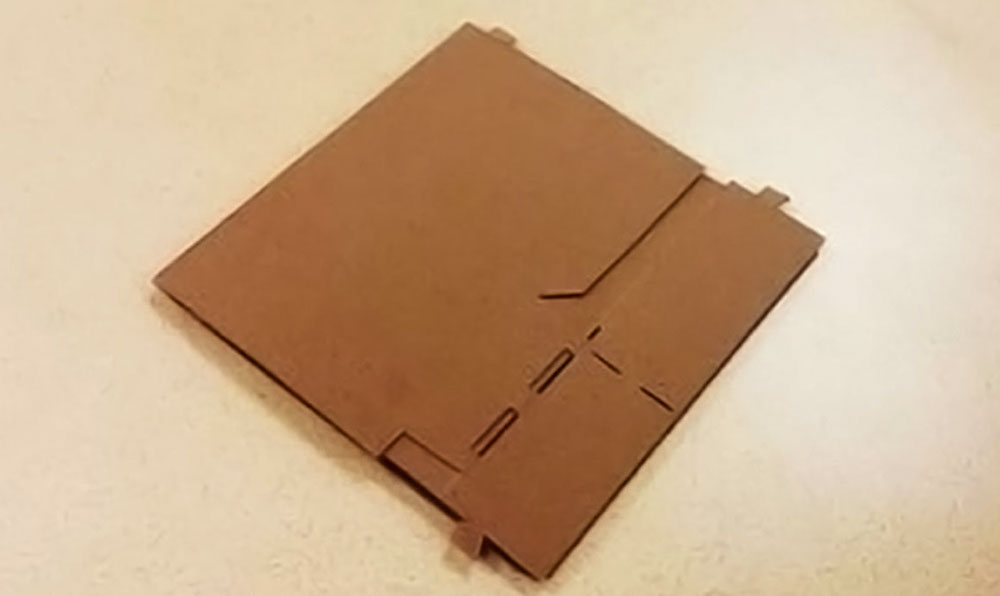

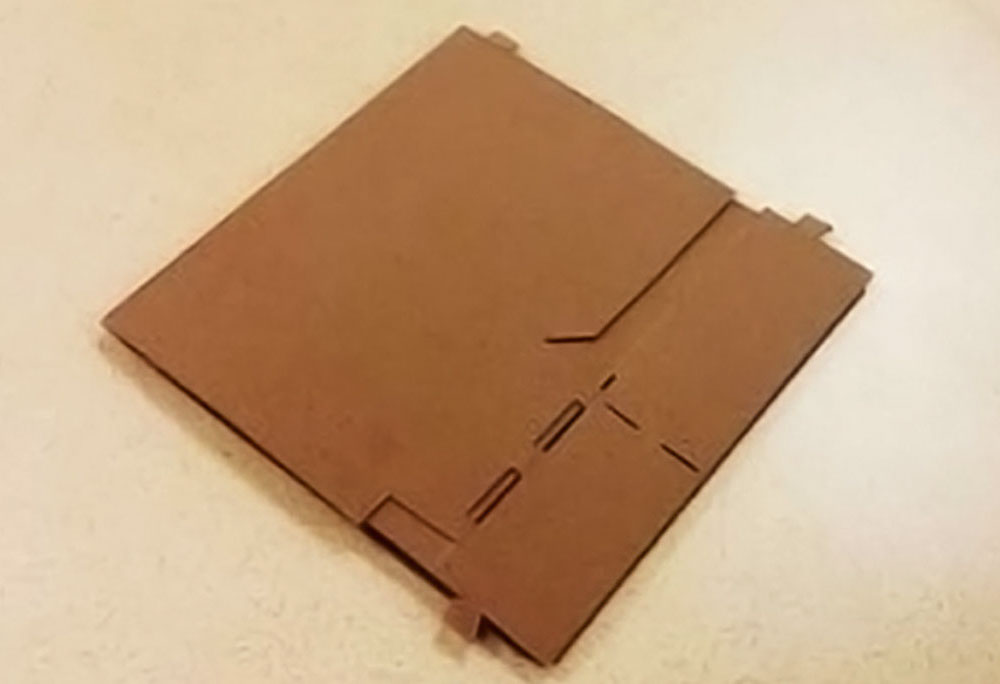

Prototype 1 PAPER & STRING

Prototype 2 FOAMCORE

Prototype 3 CARD

Return Policy

Purchase

When a customer comes to McDonald’s for take-out, the BAO box will be handed to them. The hamburger, french fries, and the drink will already be in it. The return policy and QR code will be printed on the take-out packaging. Then the Cashier will scan the QR code and record the customer’s phone number to get the box and customer information logged in the system.

Recycle

When the customer is finished with his/her food and is ready to return the package, he/she will go to McDonald’s and come to the return station. He/she will flatten the box by folding it easily. Return packaging can be done at any McDonald’s restaurant. The return station will scan the QR code and record the customer’s phone number to accumulate 'Mpoints'.

Earn

2 Mpoints = return < 7 days

1 Mpoint = return < 30 days

Spend

3 Mpoints = Coffee

6 Mpoints = 1 Hamburger

12 Mpoints = Big Mac meal

Reimburse

In front of the kiosk, there are 3 steps for returning the box. The QR code was on the corner of the box surface. First, the customer puts the folded box in the target area, and the information of box and the customer are logged into the system again to confirm that the box is returned and the Mpoints were given to the customer. Then the customer puts the box in the inclined slot. And the box will slip into the kiosk.

The box gets deposited at McDonald’s, sent to McDonald’s recycling unit to be de-greased, made into pulp, and then the pulp is reused to make new Bao boxes.

CONCLUSION

The Bao box reduces separate parts from three to one, making it easier and more cost-saving for manufacturing and assembly processes. Additionally, it allows much more paper that would otherwise be thrown in the trash or littered on the ground to be de-greased and recycled. The recycling policy gets customers motivated to help the environment by offering rewards. The design also provides a more comfortable way to take out fast food and can be developed further, by making the design more environmentally-concerned, and by implementing the design in other restaurants.

Reduces packaging items from

3 parts to 1 single piece

Reduce litter on the streets

Increase recycling in

fast-food industries

Provide a more comfortable way to take out food